Typically, during the construction of larger diameter pipelines; the use of x-ray crawlers, real-time radiography, and automated ultrasonic girth weld techniques, can be used to exponentially increase production, improve quality and create huge savings. TechCorr’s pipeline division was formed specifically to focus on the construction of large diameter long-distance pipelines, offering a range of solutions operated by experienced pipeline professionals.

Pipeline NDT

- Home

- Pipeline NDT

Pipeline NDE

Real-time radiography (RTR), or real-time radioscopy, is a nondestructive test (NDT) method whereby an image is produced electronically, rather than on film, so that very little lag time occurs between the item being exposed to radiation and the resulting image.

Real-time radiography (RTR), or real-time radioscopy, is a nondestructive test (NDT) method whereby an image is produced electronically, rather than on film, so that very little lag time occurs between the item being exposed to radiation and the resulting image.

WORK POWERHOUSE

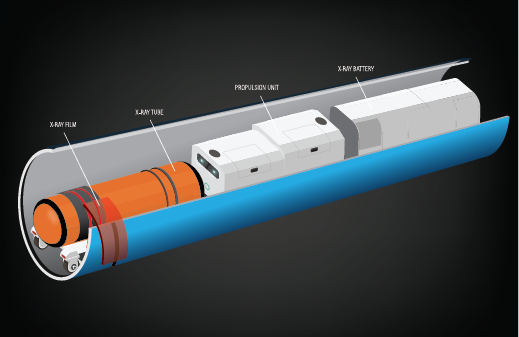

A single x-ray crawler can shoot upwards of 200 welds per shift – typically four to eight times the production of a gamma-ray crew, depending on diameter and wall thickness. X-Rays produce high-quality images versus grainy images produced by gamma rays enabling improved film interpretation.

COST EFFICIENCY

At a fraction more than a conventional gamma crew yet 4-8x the production – reduce project costs.

REDUCED OPERATOR DOWNTIME

The modular design also allows the operator to exchange components quickly – reducing operator downtime versus competing systems

TechCorr’s Inspection utilizes the PipeWIZARD® Phased Array (PA) system—combined with a global team of certified operators—to provide our customers with today’s most comprehensive Automated Ultrasonic Testing (AUT) girth weld inspection services. This world-class system enables advanced inspection techniques and real-time reporting, so the same equipment can be used for high-production and specialized weld inspections. Elevated production rates are possible with no sacrifice in quality.

PipeWIZARD is ASTM E-1961, API 1104, and DNV-OS-F101 capable. All TechCorr Inspection PipeWIZARD operators are UT-certified Level II or higher and can be rapidly deployed to both onshore and offshore locations.